DuraLink™ DOT Air Brake Tubing

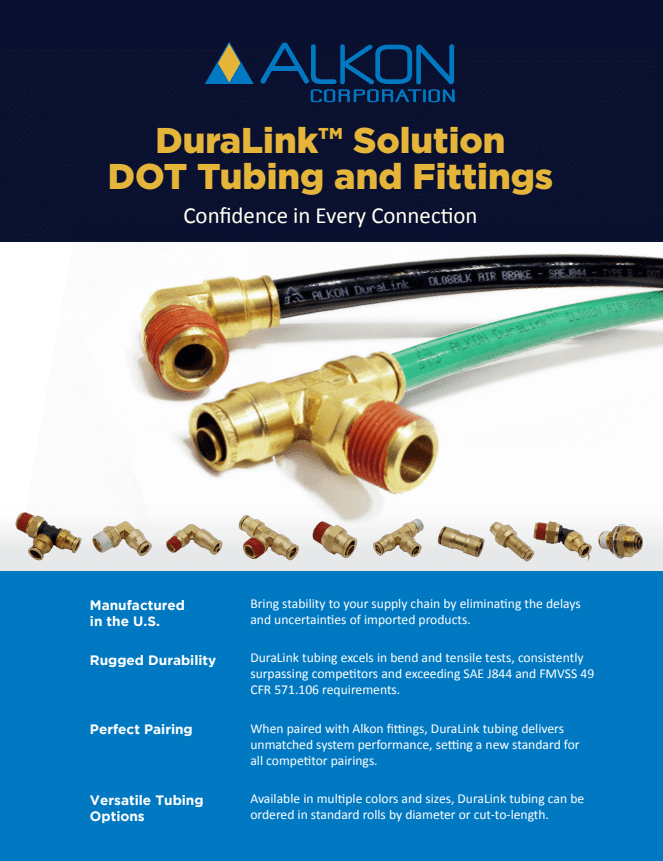

Introducing Alkon’s DuraLink™ tubing, a high-performance DOT air brake solution designed for strength and reliability. Part of the Alkon DuraLink™ product family, this tubing pairs with our proven DOT push-to-connect fittings to deliver industry-leading durability and performance. It surpasses DOT FMVSS 49 CFR 571.106 and SAE J844 standards, with tensile strength far exceeding competitors and superior bend-test results.

While optimized for Alkon’s DuraLink™ fittings, the tubing maintains trusted performance when paired with other manufacturers’ products. Available in multiple sizes and colors, DuraLink™ tubing provides the flexibility needed for new builds or repairs.

DuraLink™ tubing reflects our commitment to U.S. manufacturing, ensuring fast, dependable delivery and a stable supply chain.

“Alkon’s DuraLink™ DOT tubing and fittings are engineered to perform together, delivering unmatched reliability, performance, and peace of mind in every air brake connection.” – Rich Yori

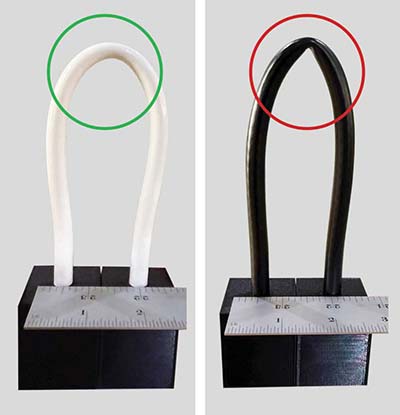

Bend Test:

Alkon DuraLink™ –

No Kinking

Bend Test:

The Other Guys

Trusted Performance For Every Connection

Rigorous testing confirms that the DuraLink Solution exceeds SAE requirements and outperforms both U.S.

and import competitors. From tensile strength to elongation and bend integrity, these results show why the complete

DuraLink Solution delivers durable, reliable air brake performance.

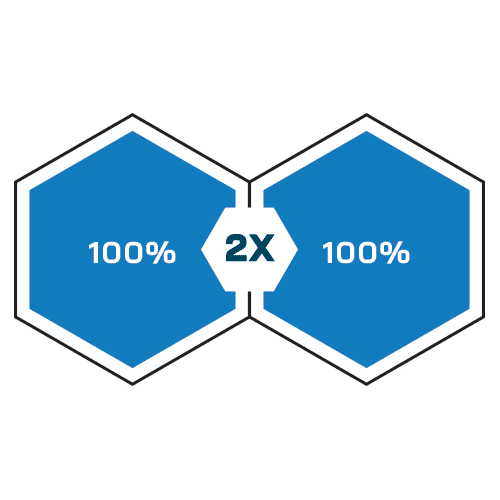

The Alkon DuraLink products have 2 times the tensile loading as required by SAE.

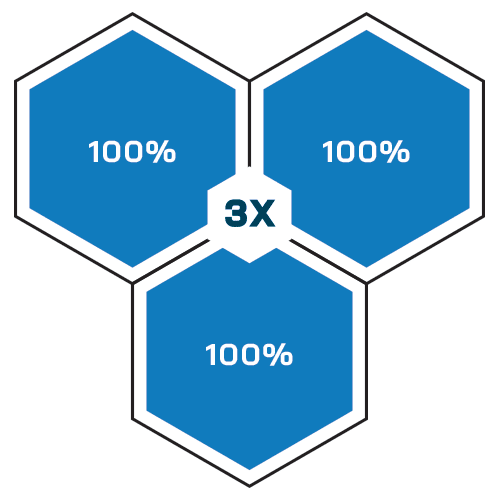

Alkon DuraLink products have 3 times the required elongation.

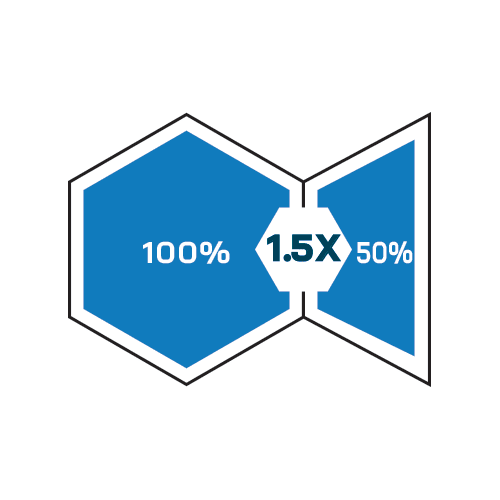

Using DuraLink tubing increases the performance of competitor fittings by 1.5 times.

Import products fall 50% short of Alkon tensile performance and FAIL TO MEET SAE STANDARDS.

Domestic and import fittings and tubing exhibit 20% of the DuraLink elongation performance and FAIL TO MEET SAE STANDARDS.

Design Specifications

| Tube Size O.D. | ||||||

|---|---|---|---|---|---|---|

| Tube Size | Tube O.D. | Wall Thickness | Type | Material | Min. Burst Pressure | Min. Bend Radius |

| 5/32 | 5/32″ | .032″ | A | Nylon | 1200 psi | 1/2″ |

| 04 | 1/4″ | .040″ | A | Nylon | 1200 psi | 1″ |

| 06 | 3/8″ | .062″ | B | Reinforced Nylon | 1400 psi | 1-1/2″ |

| 08 | 1/2″ | .062″ | B | Reinforced Nylon | 950 psi | 2″ |

| 10 | 5/8″ | .092″ | B | Reinforced Nylon | 900 psi | 2-1/2″ |

| 12 | 3/4″ | .092″ | B | Reinforced Nylon | 800 psi | 3″ |

Tubing Material: Nylon

Maximum Working Pressures: 145 psi

Operating Temperatures Range: -40ºF to +200ºF

Compliance Standards: SAE J844 and FMVSS 49

CFR 571.106

Environmental Resistance: Withstands extreme

temperatures and road conditions.

Tubing Part Numbers

| Tube Size O.D. | |||||

|---|---|---|---|---|---|

| 5/32″ | 1/4″ | 3/8″ | 1/2″ | 5/8″ | 3/4″ |

| DL5/32BL1000 | DL04BL1000 | DL06BL500 | DL08BL500 | DL10BL250 | DL12BL250 |

| DL04BLU1000 | DL06BLU500 | DL08BLU500 | DL10GN250 | DL12BLU250 | |

| DL04GN1000 | DL06GN500 | DL08GN500 | DL10O250 | DL12GN250 | |

| DL04GY1000 | DL06GY500 | DL08O500 | |||

| DL04O1000 | DL06O500 | DL08R500 | |||

| DL04PU1000 | DL06PU500 | DL08Y500 | |||

| DL04R1000 | DL06R500 | ||||

| DL04WH1000 | DL06WH500 | ||||

| DL04Y1000 | DL06Y500 | ||||

Cap Color Part Numbers

| Tube Size O.D. | |||

|---|---|---|---|

| 5/32″ | 1/4″ | 3/8″ | 1/2″ |

| AQCAP-D-5/32O | AQCAP-D-4BR | AQCAP-D-6B | AQCAP-D-8B |

| AQCAP-D-4BL | AQCAP-D-6BL | AQCAP-D-8GN | |

| AQCAP-D-4GN | AQCAP-D-6GN | AQCAP-D-8GR | |

| AQCAP-D-4Y | AQCAP-D-6GR | AQCAP-D-8O | |

| AQCAP-D-6O | AQCAP-D-8R | ||

| AQCAP-D-6R | AQCAP-D-8V | ||

| AQCAP-D-6V | AQCAP-D-8Y | ||

| AQCAP-D-6Y | |||

Additional Resources

Alkon DuraLink Solution

Alkon DuraLink Solution:

DOT Tubing & Fittings

(PDF, 4 MB)

DuraLink Tutorial

Learn how DuraLink Tubing

and Alkon fittings team up for

unbeatable performance.

Frequently Asked Questions

DuraLink™ DOT tubing is Alkon’s high-performance nylon tubing, engineered for demanding air brake and air suspension systems. Made in the U.S., it is DOT-compliant and meets the Federal Motor Vehicle Safety Standard (FMVSS) 49 CFR 571.106 and the Society of Automotive Engineers (SAE) J844.

Part of the DuraLink™ Solution, it provides secure, leak-resistant connections for both new builds and repairs. Its construction withstands vibration, pressure changes, and extreme temperatures, delivering consistent operation in demanding conditions.

Alkon DuraLink™ DOT tubing undergoes rigorous in-house testing to meet SAE J844 and FMVSS 49 CFR 571.106 standards. These tests simulate real-world air brake and air suspension conditions, ensuring leak-free, durable, and safe connections.

Key performance highlights:

- Tensile Strength: Nearly 2x the SAE peak load requirement

- Elongation: 3x the required elongation

- Bend Performance: Maintains integrity at tight bend radii

- Operating Temperature: Performs reliably from -40°F to +200°F

These results give fleets and OEMs confidence that DuraLink™ tubing will perform reliably in every installation.

Alkon DuraLink™ DOT tubing consistently outperforms U.S. and imported alternatives:

- Elongation: Competitor fittings and tubing achieve only 20% of DuraLink™’s elongation

- Tensile Strength: Many import fittings and tubing fall up to 40% below Alkon standards

- Bend Integrity: While competitor tubes may fail under tight bends, DuraLink™ retains its shape and function

These performance advantages reduce maintenance and downtime, making DuraLink™ a reliable choice for DOT-compliant air brake and suspension systems.

Yes. DuraLink™ tubing is compatible with other manufacturers’ fittings and can improve their performance. Internal testing shows that pairing competitor fittings with DuraLink™ tubing delivers:

- Up to 145% increase in elongation

- Up to 43% increase in tensile strength

For the best overall performance, use the full DuraLink™ Solution. Combining DuraLink™ DOT tubing with Alkon push-to-connect fittings delivers unmatched system durability and DOT compliance.

Air brake systems rely on both tubing and fittings. Even the best fittings cannot compensate for inadequate tubing. Low-quality tubing can stretch, crack, or pull out under pressure, resulting in air leaks or system failure.

DOT-compliant tubing maintains consistent air pressure, safe braking, and long-term operation, protecting fleets from downtime, costly repairs, and safety risks. According to the Federal Motor Carrier Safety Administration (FMCSA), brake issues contribute to 45.5% of large truck crashes, highlighting why every component must perform reliably.

DuraLink™ DOT tubing is available in multiple diameters and colors. It can be ordered in standard roll lengths or cut-to-length to meet the needs of new builds and repairs.

Choosing the complete Alkon DuraLink™ Solution ensures peace of mind in every connection and delivers high-performance air brake reliability that cannot be achieved by mixing components.

The full solution works together to provide three key advantages for fleets and OEMs:

- Proven System-Level Performance: Alkon’s in-house testing shows the DuraLink™ Solution delivers higher tensile strength, greater elongation, and improved overall durability than any mixed-component pairing.

- North American Manufacturing: Producing both tubing and fittings in North America ensures consistent materials, controlled processes, and quality, supporting dependable lead times and a stable supply chain.

- Compliance with SAE and FMVSS Standards: Every DuraLink™ Solution is engineered in accordance with SAE J844 and DOT FMVSS 49 CFR 571.106, giving fleets and OEMs confidence that it meets or exceeds all DOT requirements.

For more information on Alkon DOT fittings and compliance, click here.